ACHIEVING TOP-TIER QUALITY

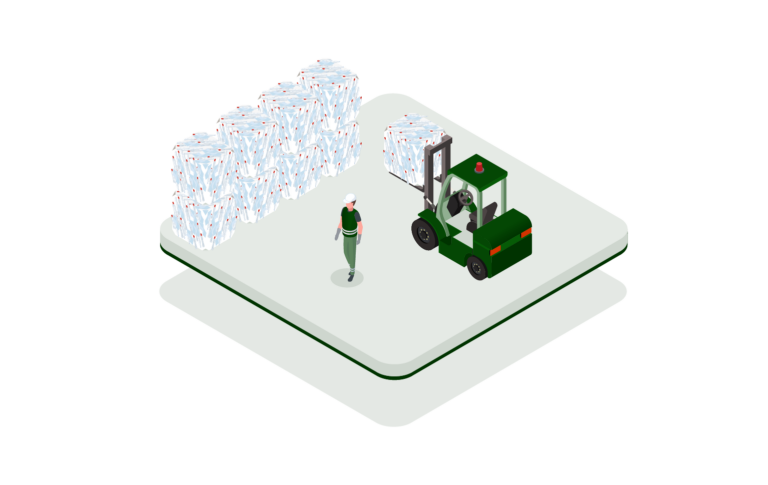

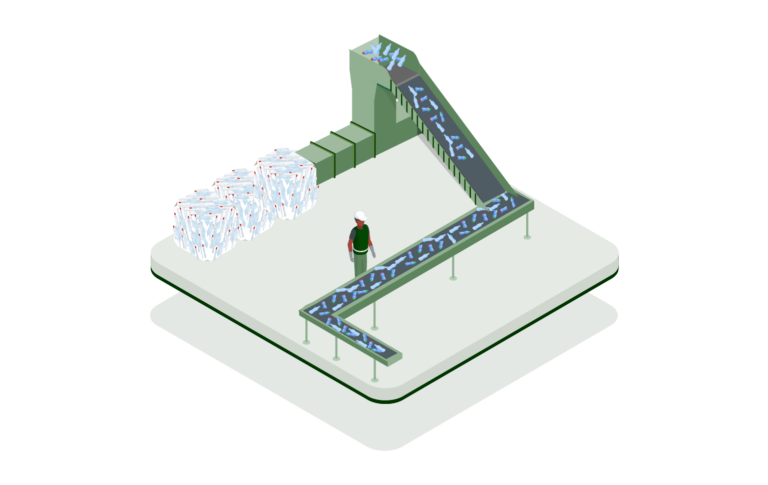

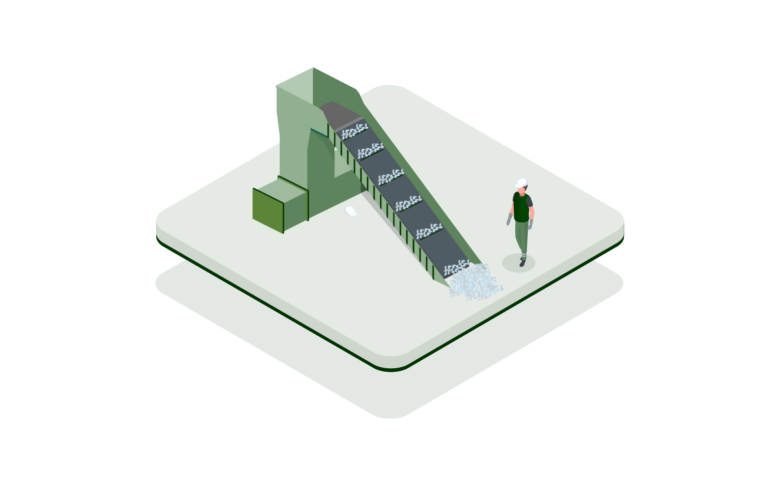

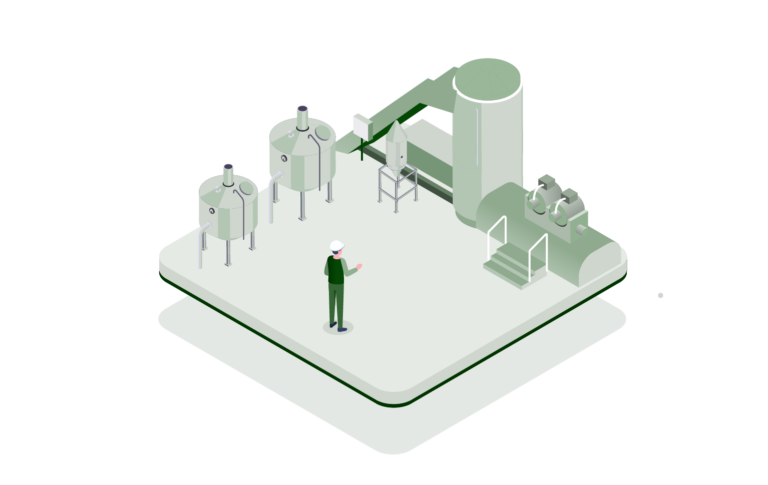

Our Process

At Vertix, our recycling process for Natural and Mixed HDPE involves a host of procedures promising a product of the highest quality and transparency. Our products meet stringent quality parameters providing our customer with top-tier materials for all manufacturing needs.

LEARN THE PROCESS

QUALITY ENSURED

Ensuring the highest standards is fundamental at Vertix. We meticulously test and evaluate our pellet products before shipping to our valued clients. In our production process, we integrate stringent quality checks at every stage, including third-party testing, assessing recycled plastics and flake products for impurities to establish the parts per million (PPM) level of contamination.